Overview: Typical Custom Flag Cost Range

Custom flags vary in price. Most businesses and individuals invest $50 to $300 per flag for standard custom flag printing services. This range shifts based on your specific needs.

Here's what the pricing looks like:

Premium U.S.-Made Nylon Flags: The gold standard for quality runs $100 to $200 for a single custom flag. Companies like Custom Flag Company position these as durable, long-term investments. You get superior material construction. The beauty? That per-flag cost drops when you scale up. Quantity price breaks kick in at 3, 6, 12, 25, 50, 100, 250, 500, and 1,000 units.

Budget-Friendly Imported Polyester Options: For short-term promotions, giveaways, or fundraising events, 100-denier polyester flags deliver a cheaper alternative. Exact pricing isn't always published. These imported flags undercut premium nylon, particularly in bulk. One vendor's benchmark reveals the cost efficiency: 100 standard-sized custom flags for about $1,150 total—that's around $11.50 per flag. This price can drop even more with simple designs, limited colors, or different material choices.

Oversized Custom Flags: Planning something bigger than 100 square feet? Budget $300 to $1,000+ per flag. These statement pieces command premium pricing. The reasons? Material volume, specialized production needs, and handling logistics.

The real cost driver isn't just the base price. You need to understand how flag size pricing, material types, single vs double sided flags, and order quantity work together. Smart buyers use bulk custom flag orders to maximize value. Per-unit costs can drop by 80% or more.

Key Factors That Determine Custom Flag Cost

Your final price depends on several connected factors. Each choice you make shifts the cost—sometimes by a lot.

Physical Dimensions Matter Most

Flag size controls how much material you need and how complex production gets. An 8.5 ft flag costs 15-20% less than the standard 11.5 ft version. Go bigger? Expect to pay 25-40% more for 15 ft flags and 50-75% more for 18 ft giants. That math adds up fast across multiple units.

Material Grade Changes Everything

Standard 110 gsm polyester sits at baseline pricing. Upgrade to 150 gsm or 200 gsm premium materials and you'll add $5-15 per flag wholesale. UV-resistant coatings cost more. But they give you better fade resistance for outdoor use.

Printing Sides Double Your Investment

Double-sided flags need twice the fabric and two printing runs. Budget 60-80% more than single-sided versions. Real example: one 8 ft double-sided flag ran $128 production + $65 setup + $15 shipping = $208 total landed cost.

Design Complexity Adds Premium Charges

Simple text designs hit the low end of pricing tiers. Want full-color photo reproduction with PMS color matching? Add 15-30% above base wholesale prices. More ink coverage means more color management. And that means higher costs.

Hardware and Finishing Details

Reinforced headers, special grommets, and pole sleeves increase per-unit costs. Many promotional flag packages bundle the flag, pole, and ground spike together. Buying each piece on its own drives up your total system cost.

Flag Size

Dimensions dictate your budget more than any other variable. A 3 ft × 5 ft flag sets the baseline pricing for most custom flag printing services. Move up to 4 ft × 6 ft? You're looking at a 20-35% price jump. Scale to 5 ft × 8 ft, and costs climb another 40-60% from baseline.

Flag size pricing follows a simple rule: cost increases with square footage, not in a straight line. Double your dimensions? You'll pay 3-4 times more, not twice as much. Production gets more complex. Material waste goes up. Handling needs more work. All these factors drive costs higher than the size suggests.

Standard Size Tiers and Price Breakpoints

Manufacturers use established size categories for pricing:

Small Format Flags (Under 20 sq ft)

- 2.5 ft × 4 ft (10 sq ft): Entry-level pricing, perfect for handheld or small residential displays

- 3 ft × 5 ft (15 sq ft): The industry standard – most competitive pricing per square foot

- Best for: Individual purchases, residential flagpoles under 20 feet, indoor displays

Medium Format Flags (20-50 sq ft)

- 4 ft × 6 ft (24 sq ft): Common for schools and small commercial buildings

- 5 ft × 8 ft (40 sq ft): Standard for hospitals and 3-5 story buildings on 30-foot poles

- Pricing sweet spot for bulk custom flag orders – manufacturers stock these sizes

Large Format Flags (50+ sq ft)

- 8 ft × 12 ft (96 sq ft): Dealerships, government buildings, 40-foot poles

- 10 ft × 15 ft (150 sq ft): Major commercial installations

- 20 ft × 38 ft and larger: Custom manufacturing required, $800-$3,000+ per flag

Matching Flag Size to Application

Pick dimensions based on your flagpole height. The universal rule: flag length should equal 1/4 to 1/3 of pole height. A 20-foot residential pole works best with a 3 ft × 5 ft flag. That same flag on a 40-foot commercial pole? It looks small and cheap.

Wrong sizing kills your visual impact. Plus, it wastes money on replacements. Too large, and wind stress destroys the flag fast. Too small, and you lose brand visibility.

Order Quantity (Bulk Discounts)

Buy more flags. Pay less per flag. Suppliers set clear quantity breaks—cross them and your savings jump fast.

Most discount tiers work like this:

5% off at 100+ units

10% off at 500+ units

15% off at 1,000+ units

These percentages cut your total order cost. Stock needs to be available. But here's the twist: discount structures vary.

All-Units vs Threshold Pricing Models

All-units discounts drop the price on every flag once you hit the minimum. Here's an example: flags cost $10 each. Order 105 units. You pay $8 per flag for all 105 units—$840 total. Order just 99 units? You pay $990 at full price. Add 6 more flags. Save $150.

Threshold discounts work different. They cut prices on units past the break point. Same $10 base price, 20% discount at 100 units: your first 100 flags cost $1,000. The next 20 cost $8 each for $160. Total for 120 flags: $1,160. Compare that to all-units pricing on 120 flags at $8 each—just $960. That's a $200 gap.

Tiered Volume Structures

Big volume orders get bigger discounts:

0–49 units: full price

50–99 units: 10% off

100–149 units: 15% off

150–199 units: 25% off

200+ units: 35% off

Order 250 custom flags? You save 35% on everything—not just units over 200. This setup rewards big orders. Schools ordering spirit flags get this benefit. Dealerships buying branded banners get it too. Event companies stocking inventory see the same gains.

Calculate your break points before you order. Add 10-20 extra flags sometimes. This bumps you to a better tier. Your cost per unit drops hard.

Flag Material

Three fabrics rule the custom flag market: nylon, polyester, and cotton. Your choice impacts upfront cost and how long the flag lasts. Choose poorly? You'll buy replacements twice as fast.

Nylon: The Versatile Standard

200-denier nylon works best for most climates. This light fabric moves in even the gentlest breeze. That matters for brand visibility on calm days. It dries fast, so mildew stays away. UV-resistant treatments like SolarGuard® keep colors bright longer.

Premium nylon includes Nyl-Glo®. This parachute cloth gets 100% SolarGuard treatment. You get a 1-year ColorFast guarantee. Sizes range from 12" × 18" up to 30' × 60'.

Need indoor ceremony flags? Federal Artglo® mixes nylon taffeta with Rayon Bemberg yarn. The result is a high-gloss finish. These specialty grades cost $15-40 per flag more than standard nylon.

Polyester: Heavy-Duty Protection

2-ply spun polyester is the strongest flag fabric you can buy. It lasts the longest too. Made to handle harsh sun, strong winds, dirt, and moisture.

Tough-Tex® heavyweight polyester has an open-weave design. This cuts down fabric stress in high wind. Great for commercial sites, dealerships, and tough climates. Sizes run 3' × 5" through 30' × 60'. Comes with a 1-year ColorFast guarantee.

Polyester costs $8-20 more per flag wholesale than nylon. Got large flags over 10' × 15'? Reinforced polyester saves your money by preventing wind damage.

Cotton: Indoor Excellence

Natural cotton gives you rich, true colors. Works best for indoor displays and ceremonial use. Cotton fails in wet weather. Don't use it outdoors. Gold rayon fringe often goes with cotton for formal events.

Pick your material based on where you'll fly it: nylon for house poles and light wind, polyester for high-wind areas and strong sun.

Print / Construction Method

Two printing technologies work best for custom flags: screen printing and dye sublimation. Each method gives different quality, cost, and visual results. Your choice impacts both upfront cost and how long your flag lasts.

Screen Printing: The Traditional Volume Champion

Screen printing works great for simple designs with 1-4 solid colors. The process pushes ink through mesh screens—one screen per color. Setup costs run $25-75 per screen. Screen printing makes financial sense for bulk custom flag orders of 50+ units.

Here's the math: 100 flags with a 2-color design need 2 screens at $50 each = $100 setup. Split across 100 flags, that's $1 per flag in setup cost. Order just 10 flags? Setup jumps to $10 per flag. The base printing cost stays around $8-15 per flag for standard sizes.

Screen printing gives you opaque, vibrant colors that pop against fabric. Colors stay true for 2-3 years outdoors with quality inks. Complex designs with gradients or photo images? Screen printing can't handle them well. You'd need too many screens. Cost gets too high.

Dye Sublimation: Full-Color Photo Quality

Dye sublimation turns your digital design into gas. Heat bonds the gas into polyester fibers. No setup screens needed. Zero setup fees make single custom flags affordable.

This method handles unlimited colors and photographic detail. Gradients, shadows, complex logos—everything prints just right. The process soaks into fabric instead of sitting on top. Colors show through both sides, though the reverse appears 50-60% lighter than the front.

Per-flag printing costs run $12-25 for standard sizes. Higher than screen printing for large volumes. Dye sublimation works on polyester fabrics alone. Cotton and nylon won't accept sublimation dyes. This limits your flag material choices for outdoor vs indoor use.

Print quality changes flag options and final pricing. Simple text logos? Screen printing cuts costs on big orders. Complex brand marks with multiple colors? Dye sublimation gives better visual results worth the extra cost.

Single‑Side vs Double‑Sided

Pick single-sided or double-sided printing. This choice changes your custom flag cost by 60-100%. The price gap is real. Visibility changes too.

Single-sided flags print your design on one fabric layer. The image shows through on the back at about 30-40% opacity. Colors look faded from behind. Text reads backwards. Most buyers take this trade-off to save money.

Double-sided flags use two fabric layers sewn together. Your design prints sharp on both sides. No show-through. No reversed image. People see your brand right from every angle. The catch? You pay for double the fabric and two complete print runs.

Real Cost Impact on Your Order

Here's the math for a standard 3 ft × 5 ft custom flag:

Single-sided: $45-75 per flag

Double-sided: $85-140 per flag

That's $40-65 more per flag for double-sided. Order 100 flags for a dealership? The gap hits $4,000-6,500 in extra cost. Scale matters.

How you build the flag affects outdoor performance. Single-sided flags weigh less. They move better in light wind. Double-sided flags are heavier. They resist wind more. You get better durability but less movement in calm air.

Making the Right Choice for Your Application

Pick single-sided for flags facing one main direction. Residential flagpoles fit this. Store banners against buildings too. Bulk custom flag orders on a budget win here. The back view doesn't matter if no one sees it.

Pick double-sided for flags in open spaces. Traffic islands. Pole displays standing alone. Convention booths. Anywhere people walk around your flag. Your brand looks consistent from all angles. This justifies the 60-80% price jump.

One supplier's quote shows it: an 8 ft double-sided custom flag costs $128 production + $65 setup + $15 shipping = $208 total. The single-sided version costs about $115-130 delivered. You pay $75-90 extra for full 360-degree branding.

Most promo flag packages come single-sided. You get good visibility at the best price. Upgrade to double-sided just for locations where viewing angles need it.

Finish and Hardware

Grommets, pole sleeves, and reinforced stitching separate flags that last 18 months from ones that shred in 6 weeks. Standard hardware packages add $8-15 per flag to your base cost. Premium finishing options push that to $20-35 extra. This durability impacts your cost-per-wear.

Standard Hardware Configurations

Grommets are the go-to choice. Metal eyelets get punched through reinforced canvas header tape. Most suppliers use brass or nickel-plated steel grommets spaced 18-24 inches apart. Standard setup puts grommets on the hoist side (left edge). Basic grommet installation runs $3-6 per flag.

Pole sleeves suit vertical displays better. Think feather flags and street banners. The fabric folds over to create a pocket. Your pole slides through. Wind stress spreads out across the whole flag. Pole sleeve construction costs $5-8 more per flag than grommets. The trade-off? Smoother movement and better gust handling.

Reinforced stitching matters more than most realize. Double-stitched or quad-stitched hems resist fraying. Quality makers use lock-stitch or chain-stitch patterns with UV-resistant thread. Four rows of stitching on the right edge stop the most common failure point. Premium stitching adds $4-7 per flag. You get 40-60% longer outdoor lifespan.

Hardware Material Impact on Price

Stainless steel grommets cost $2-4 more per flag than standard brass. Go with these for coastal spots or high-humidity areas. Salt spray won't corrode them. The ASTM B117 salt-spray rating hits 500+ hours before breaking down.

Rust-resistant snap hooks and carabiners run $3-8 per set. Most flag packages skip these. You buy them on your own. Cheap zinc-plated clips fail in 8-12 months outdoors. Stainless steel or powder-coated aluminum clips last 3-5 years.

Canvas header tape with webbing reinforcement stops grommet tear-out. This upgrade costs $5-10 per flag. It cuts replacement frequency in half for flags larger than 5 ft × 8 ft.

Country of Manufacture (USA vs Imported)

The flag industry has two main sources: U.S.-manufactured and imported. Your choice affects price by 30-50%. It also changes lead times, quality, and how your brand looks.

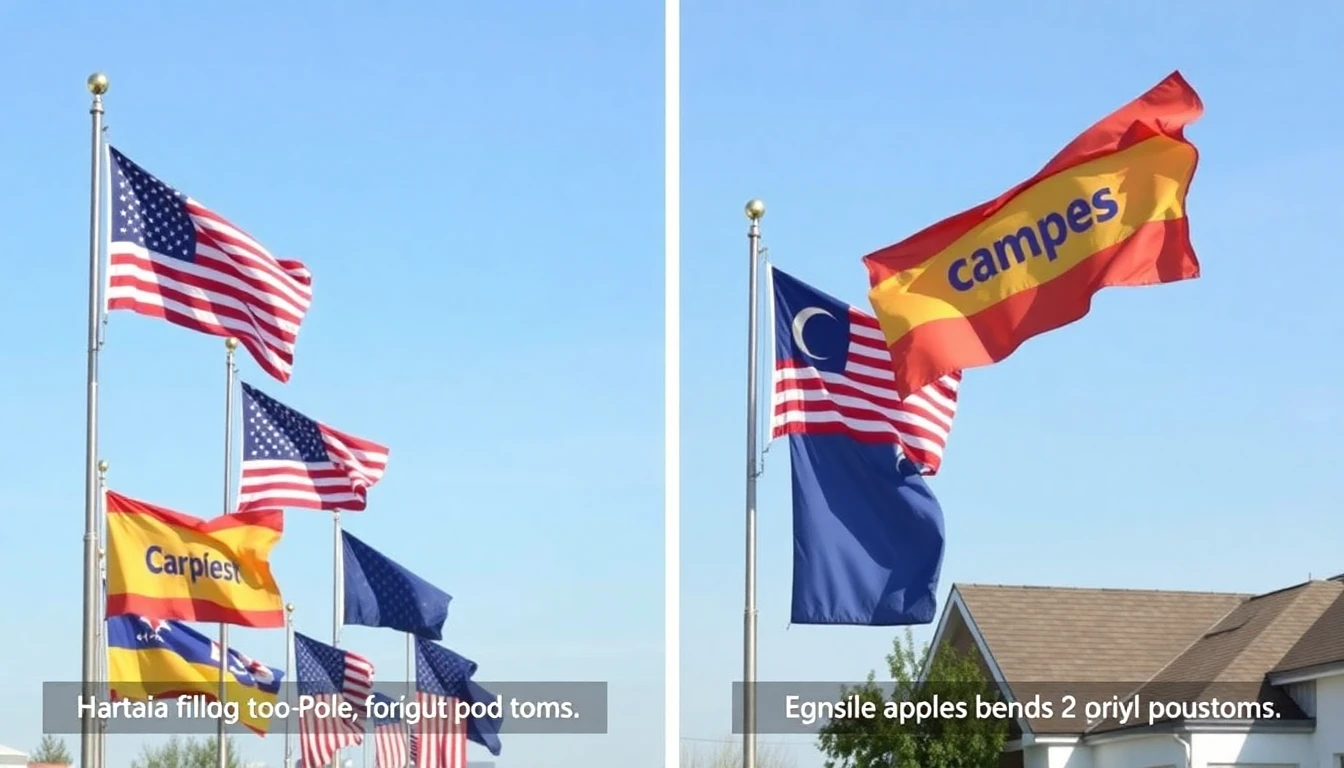

U.S.-made custom flags cost more at the start. Premium nylon flags from domestic makers run $100-200 per unit for standard sizes. You pay for strict labor rules, environmental standards, and tight quality checks. Carrot-Top Industries makes flags at their North Carolina plant. Annin Flagmakers runs their New Jersey operation. These flags last 2-3 years outdoors with good care.

Imported flags come from China, Vietnam, and Bangladesh. They cut costs big time. That 100-flag order for $1,150 total ($11.50 per flag) ships from overseas. Same 3 ft × 5 ft size. Lower quality tier. The polyester runs thinner. Stitching is looser. UV-resistant coatings don't last as long. These flags survive 8-14 months in harsh sun.

U.S. trade data tells the story: goods trade deficit hit $82.9B in August 2025. Imports grew 9.2% year-over-year. Exports climbed 5.1%. Flag manufacturing follows this same path. Bulk custom flag orders now source overseas to hit low prices.

Buyer attitudes are changing. A Conference Board 2025 survey found "Made in USA" appeal dropped 18% since 2022. Just 50% of buyers say domestic origin affects their choice. 43% say it has no impact—up from 30% three years ago. Gen Z and Millennials care less about origin labels than older buyers.

Federal Trade Commission has clear rules on labels. "Made in USA" without extras means the flag is "all or nearly all" U.S.-made. All big parts and work must be domestic. Foreign content must be tiny. Claims like "Assembled in USA with imported fabric" work fine. This applies where major imported materials are used but final work happens in the U.S.

Here's how the money works: domestic flags cost $8-15 more per unit at bulk volumes (100+ units). Your savings point depends on how often you replace flags. Pay $120 for a U.S. flag that lasts 30 months? That's $4 per month. Pay $70 for an imported flag that dies in 12 months? That's $5.83 per month. The cheap option costs more long-term.

Government contracts and some company policies require U.S. manufacturing. The Berry Amendment forces Department of Defense to buy 100% U.S.-made flags. Fabric, thread, grommets—everything. Schools and city governments often have the same local-content rules. Check buying rules before you order bulk.

Lead times are different. Domestic makers ship in 7-10 business days for custom flag printing. Imported production takes 3-5 weeks by sea freight. Air freight runs 7-12 days but adds $40-80 extra shipping per order. Tight event deadlines need domestic manufacturing.

Quality control shows the biggest split. U.S. makers check every flag before it ships. Return rates stay under 2%. Imported bulk orders hit 5-12% defect rates. Color mismatches happen. Printing goes crooked. Stitching fails. Add replacement costs to your budget for big orders.