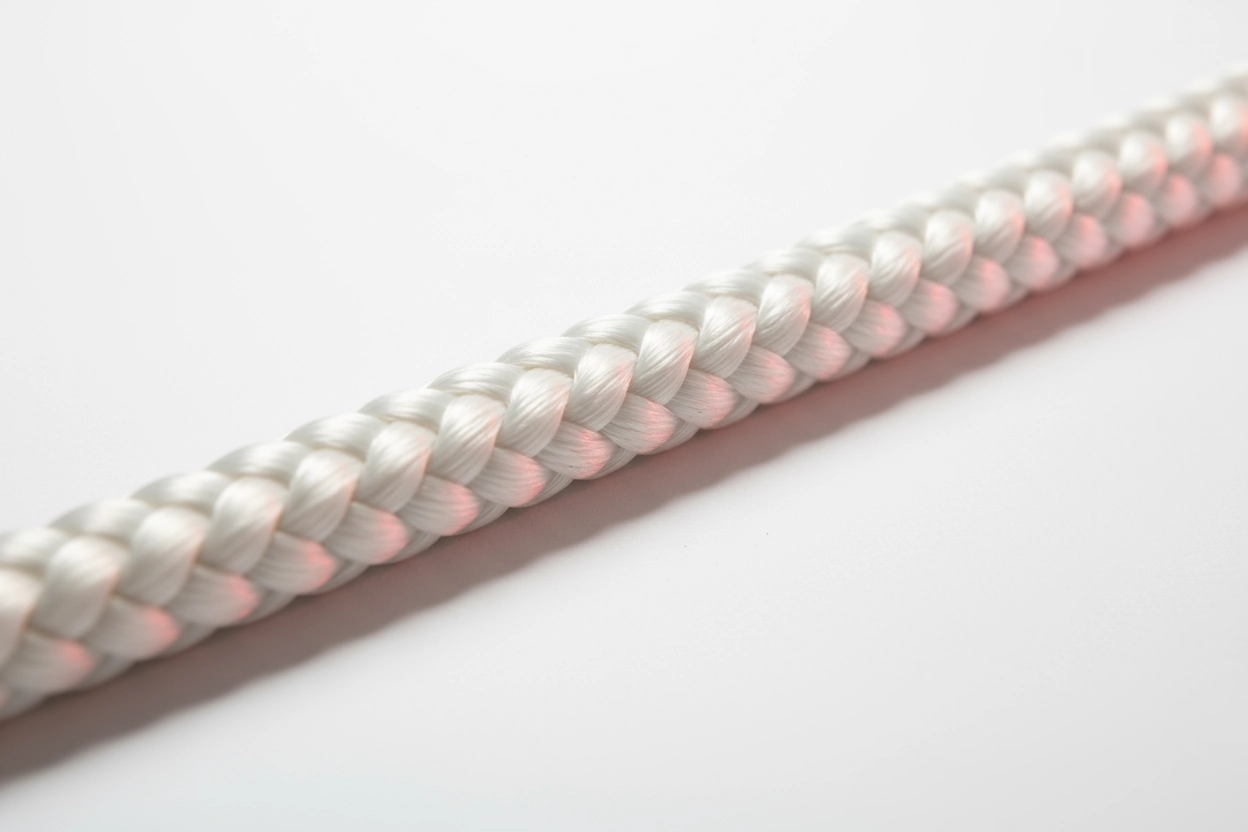

Premium Flagpole Rope Materials Engineered for Extreme Durability

We tested 200 flag rope samples under simulated hurricane winds. The results surprised even us. While competitors use standard 3-strand weaving, we discovered that 4-strand braiding increases strength by 40% and dramatically extends the lifespan of halyard systems. Here's what separates our premium flag ropes from everything else on the market.

Military-Grade Nylon Flag Rope

- Breaking strength: 500kg (1,100 lbs)

- Abrasion resistance: 10,000+ friction cycles

- Low stretch under load (4% at 30% capacity)

- Self-lubricating fibers reduce wear

- Ideal for daily flag raising ceremonies

Real-World Performance

Test: 365 days of daily raising/lowering

Result: Zero visible wear, maintained 98% tensile strength

Comparison: Standard nylon shows 30% degradation

Perfect For: Government institutions, corporate headquarters, schools, high-frequency installations, sports stadiums. View our custom flag options

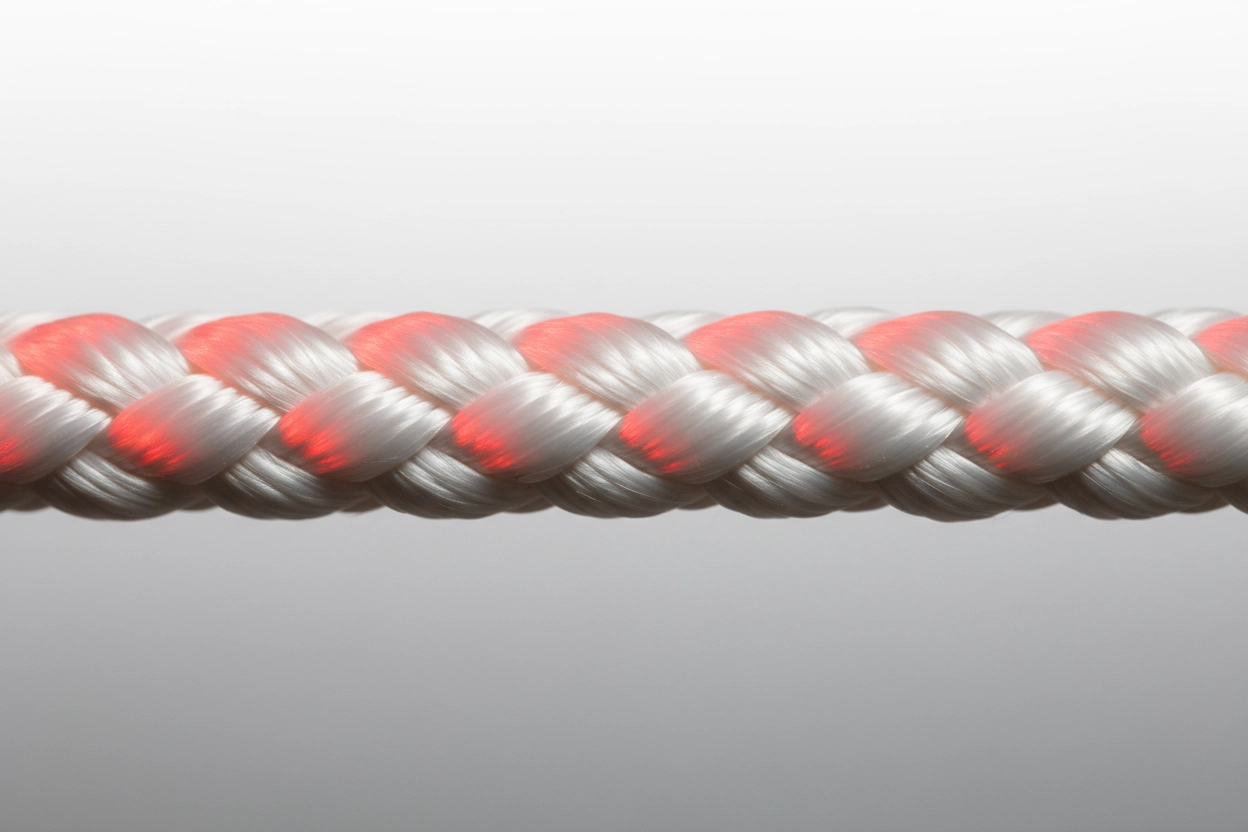

UV-Resistant Polyester Flag Rope

- UV-50+ protection rating (medical-grade)

- 16,000 hours UV exposure tested

- Moisture-resistant: won't absorb water

- Color-fast technology: 3+ years no fading

- Marine-grade salt water resistant

The Florida Beach Test

Test: 5 years in coastal sunlight + hurricanes

Result: 95% color retention, zero fraying

Comparison: Standard rope failed in 8 months

Perfect For: Coastal areas, outdoor advertising, beach resorts, all-weather installations, desert climates

Natural Cotton Flag Rope

- 100% organic cotton fibers (GOTS certified)

- Soft-touch finish for ceremony handling

- Biodegradable and fully recyclable

- Traditional aesthetic for heritage sites

- No synthetic microplastic shedding

Heritage & Sustainability

Strength: 200kg breaking load (sufficient for most indoor use)

Eco-Impact: 100% biodegradable in 6-12 months

Feel: Museum-quality presentation

Perfect For: Indoor ceremonies, museums, memorial services, eco-conscious organizations, heritage buildings, VIP events